Siemens Industrial AI: Cutting-Edge Solution for Enhancing Manufacturing Efficiency

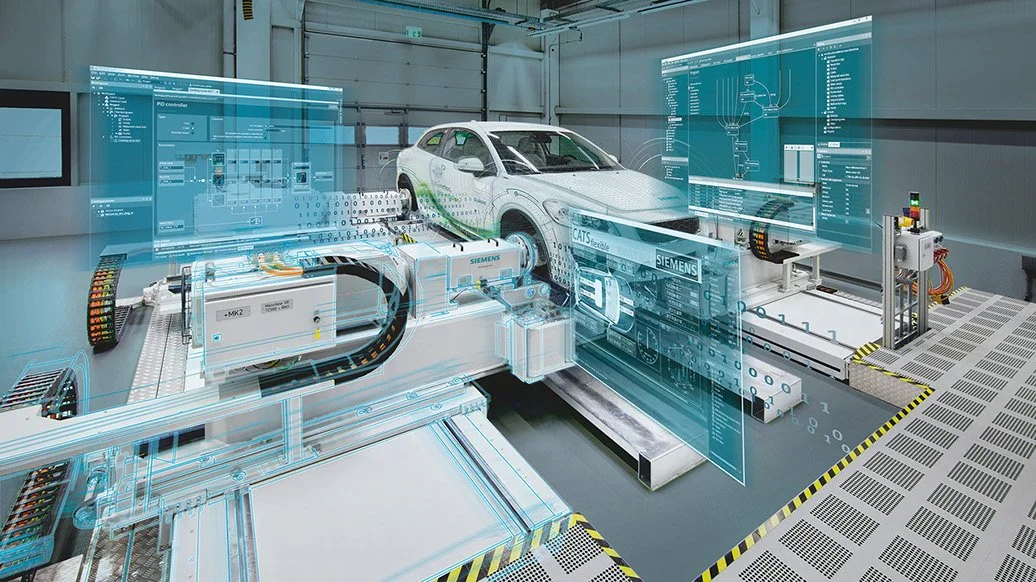

In today’s fast-paced business environment, it is crucial for companies to keep up with technological advancements and leverage new opportunities to maintain their competitiveness. Siemens Industrial AI provides a solution that integrates state-of-the-art artificial intelligence into manufacturing and enterprise processes.

One of the biggest challenges in modern manufacturing is ensuring consistent quality. Traditional human quality control methods are no longer sufficient to meet market expectations. Siemens Industrial AI, complemented by an advanced visual quality inspection system and evosoft's expertise, revolutionizes quality assurance in manufacturing processes.

Why Is Siemens Industrial AI-Based Visual Inspection Revolutionary?

In high-speed, high-volume manufacturing processes, human quality control is becoming increasingly difficult, and in many cases, impossible. Continuous product inspections are exhausting, and there is a growing shortage of skilled labor, while employee turnover remains high.

In contrast, machine-based quality control operates 24/7 without fatigue and with minimal error rates. A sophisticated camera system, combined with a properly trained neural network, can achieve a defect detection rate of 99.9%.

In certain industrial applications, hundreds of products must be inspected within seconds, a task that only an AI-based system can handle efficiently. Furthermore, AI-based machine vision can often detect defects that the human eye cannot see, such as microscopic imperfections.

Another unique advantage of the Siemens Industrial AI system is its scalability. Neural networks operating across multiple production lines can be centrally managed, monitored, and maintained.

Integration and Data Analysis

Siemens Industrial AI solutions communicate in real time with the production line and robots via the Profinet system. This enables the immediate removal of defective products, reducing the spread of rejects within the manufacturing process and preventing further losses.

The system, built on the Siemens Edge platform, ensures robust industrial performance and maximum flexibility with IT/OT integration capabilities. AI systems collect data, which is displayed on dashboards and used to generate automatic reports. Data analysis helps identify recurring defects and offers opportunities to further refine manufacturing processes.

As a result, the quality of market-ready products significantly improves. Quality control costs decrease, and costly product recalls and reputational damage can be avoided.

The data collected by the AI system, along with its dashboard visualization and automated reporting, provides valuable insights. Data analysis can highlight recurring issues, allowing for corrective measures to be implemented by modifying production processes.

This collected data provides well-founded information from production managers to senior executives, ensuring the most effective strategic decisions.

With rising production costs, it is essential to embrace every innovation, especially AI-based quality control systems, which can lead to a 30-50% reduction in quality control costs and a 10-40% decrease in waste, depending on the industry and application.

evosoft’s Role in Your Success

evosoft, as Hungary’s leading software company, possesses the extensive expertise and competencies necessary for the successful implementation of Industrial AI projects.

Our specialists are well-versed in the broad spectrum of IT/OT domains. We can flexibly address challenges in these areas, whether it involves communication with PLCs from other manufacturers or establishing connections with various databases, MES, or ERP systems. Our expert colleagues in Hungary provide local support and consultancy to our partners.

Conclusion

Siemens Industrial AI and its visual quality inspection solution, combined with evosoft’s expertise, represent not just a technological advancement but a complete paradigm shift in manufacturing quality assurance. The system not only identifies defects but also prevents them, continuously learning and evolving to ensure long-term competitiveness.

The future of manufacturing is not just automated—it is intelligent. The collaboration between Siemens and evosoft ensures that your company will be an active shaper of this future.