Simulation solutions for better production

Manufacturers and machine builders face ever-increasing demands in designing, installing and commissioning production machines. Trends in the manufacturing industry, such as shorter product life cycles, a growing number of product variants, and companies seeking cost-effective solutions in their production processes, require engineers to leverage advanced software solutions and simulations during the planning and development stages.

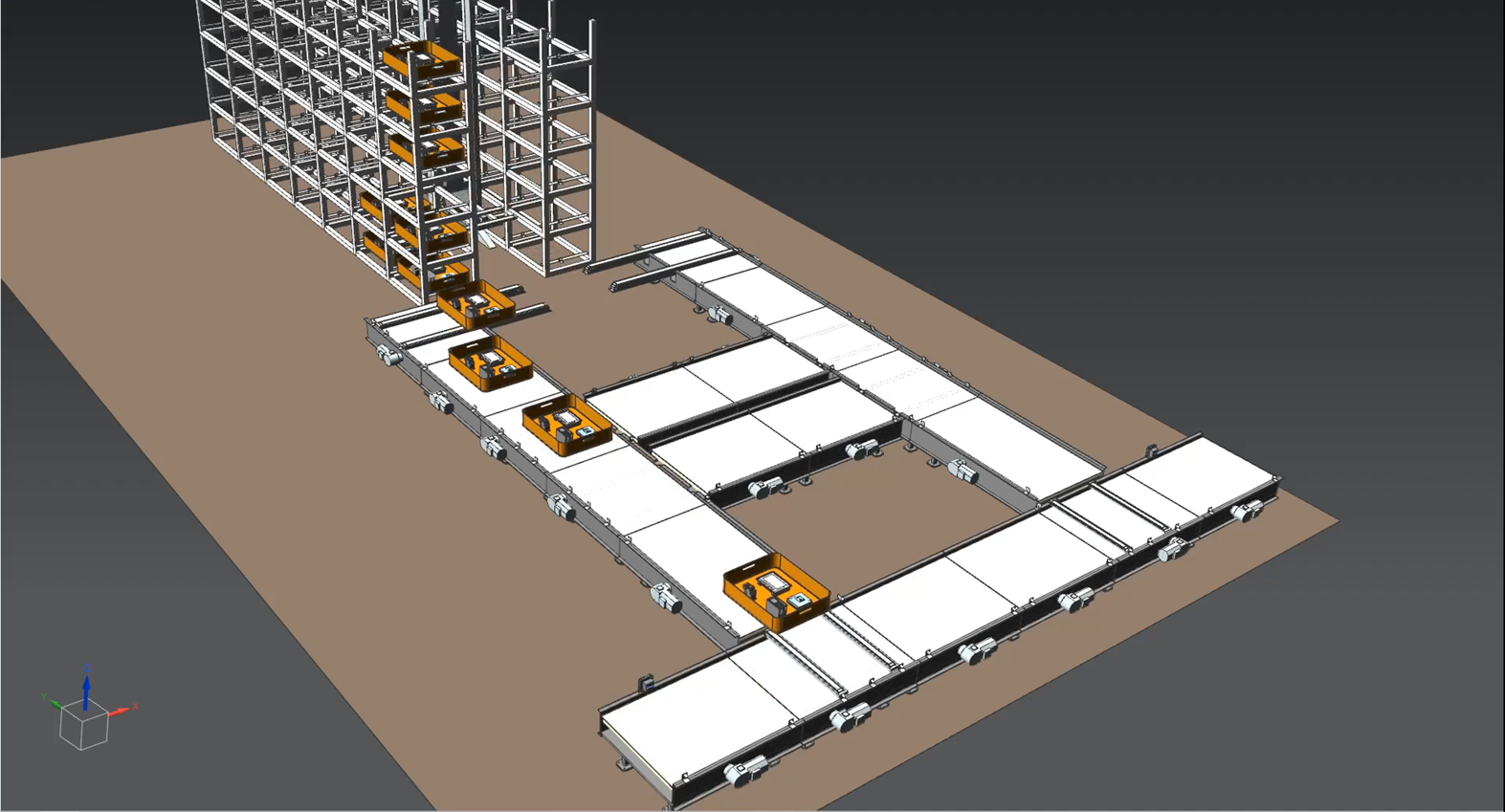

Fortunately, simulation solutions can be applied at various stages during the design and development of a machine. In the current case study, we explore two types of simulations for a fictional automated high-bay warehouse and its corresponding conveyor system. One of them is the material flow simulation which aids in determining the optimal layout, control logic and operational parameters for our machine. Once we have finalized the plans for our warehouse, we can initiate virtual commissioning, where the system’s control program is developed using a digital twin. By conducting this development simultaneously or even before the machine installation, we can reduce on-site commissioning time and save valuable project time.

We employed Siemens Plant Simulation to optimize our system during the design phase. We set specific requirements, such as the capability of the warehouse robot to handle each picking in 30 seconds and the need for redundancy in the conveyor system in case of failures. Additionally, we considered certain boundary conditions, including the size of the available area in the factory and the dimensions of the pallets.

We used the simulation to design both the layout and the control logic of the system, fine-tuning the operational speeds of the conveyors and the storage robot. The software can run simulations faster than real-time, allowing us to explore numerous scenarios within a short time interval. With the data obtained from the simulation, we can make informed, data-driven decisions regarding the system.

Once we finalized the plans for our warehouse, we commenced the development of the automated warehouse control program in a virtual environment, or more concisely, through the virtual commissioning of our system. For this, we utilized the Siemens NX software, enabling us to define the kinematics of our machine components and the necessary sensors/RFIDs. The software allows us to connect industrial control systems’ signals to the defined kinematics and sensors in the model. Subsequently our programming colleagues can begin implementing and testing the PLC program of the system. By the time the machine is physically installed, we aim to have an error-free and ready PLC program, capable of efficiency controlling the real machine.

It is important to note, that it is rare for an already existing machine to be beyond further improved. The good news is that with these simulation tools at our disposal, we can examine and optimize not only brand new machines but also those already in operation without the need to take them out of production.

With the material flow simulation, you can:

increase the efficiency and utilization of your system;

reduce storage costs and logistic lead time;

easily extract quantitative indicators of your logistic process, and

develop alternative logistic strategies.

What do you receive if you choose virtual commissioning?

You can detect errors during the design phase.

It reduces commissioning and set-up times.

It minimizes the risk of material damage.

It facilitates the training of operators.

Are you really curious?

Discover the solutions that evosoft provides.

We have prepared a few more interesting videos. Check these out too.

Simulation in intralogistics - check our blog article.

A foretaste of evosoft’s portfolio - check our blog article.

Let's get in touch, contact us.

If you are interested in our solutions and services, please send a message to our Program Manager.

Gábor Kozó - Program Manager (LinkedIn)